Testing Apparatus and Precautions

Testing a three-phase electric motor without a trip down to the repair shop requires a cautious approach, but happily all you need to start with is a volt-ohmmeter and some simple hand tools. (More advanced testing requires specialized tools. Those are described below.)

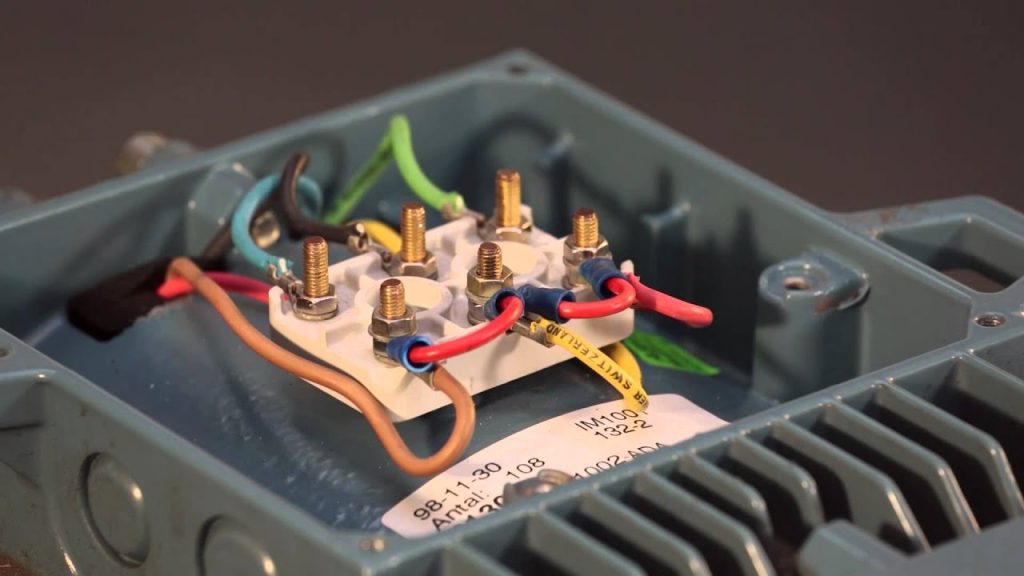

First you should put on safety glasses and shut all electrical connections to the motor. Since you’ll be testing the motor only, it’s best to first remove the connections from the power supply completely, so your next move is to identify and label the power leads to the motor cables. This step will also assure that the rotation is correct after you finish testing the motor.

Remove any wire nuts or insulation tape from the connections, and see to it that you have only exposed copper wires for testing the motor leads. Switch on your volt ohmmeter to ohms. Now connect the leads from your motor to each power connection. See to it that each reading shows only either infinite ohms or OL on the ohmmeter. However, it the reading is not OL, then it means that the motor is not good, in which case you may have to replace it.

In order to test a 3-phase motor further, you will have to conduct the following tests to find out if your motor is good or bad.

Megger Testing

Even though a fault in your motor can be found out with the help of a multimeter, still becoming doubly sure really helps. You can test your motor insulation with the help of a megger. If you want to test a 480v motor, then the voltage required would be 1000v with a reading of 2M ohms or more. The ideal mode of testing is phase to phase and phase to ground.

Next you need to conduct a threading balance check by evaluating the three phase currents. Sometimes out of balance voltage might also display unbalance as well, so you will have to be careful with this. Also conduct a rough resistance test to assure that the windings on the motor are the same.

Apart from this you can also run your motor without load, which is also a good way of testing your motor. Even though you may have to do a bit of work by splitting the coupling, this test will really help you to find out if the motor is bad or good, since it is not usual for a bad motor to run off load.

Additionally along with these tests you will also have to test your voltage, contacts contact check, terminal check, etc.

Polarization Index Test (PI)

The PI test has to be conducted for ten minutes and the voltage has to be lower than that prescribed by IEEE43. For more information about this please visit Testing Theories and Recommendations. At one minute you need to take a megohm reading and repeat it at ten minutes. This will help in finding the flexibility of the ground insulation. The particles present in the ground insulation will support that field when they are placed in an electric field. No polarization will take place if the insulation in your motor is either hard or even brittle.

The Polarization index is the relative amount of the ten minute insulation electrical resistance interpretation fractioned by the one-minute reading. The PI will be two or more with the reading increasing by the same factor of two or more. But in case of brittle insulation, the PI value will be a little more than one showing that there is no polarization taking place. One disadvantage of this test is that it helps in looking only at the ground insulation and does not display any issues with the turn-to-turn insulation.

Surge Test

In order to test the condition of winding insulation, a surge test has to be performed. Even though this test was developed 80 years ago, surge testing still forms a part of testing a 480v motor to find whether it is good or bad. Defects in turn-to-turn, coil-to-coil, and phase-to-phase that cannot be detected by other methods will be revealed by a surge test. This test is based on an assumption that in a stator without any winding errors, all the three phase windings will be indistinguishable. When this kind of test is being conducted, you will have to look for a shift towards the left by the waveform of the testing phase. The shift towards the left indicates that the turn-to-turn insulation has devolved to a grade below that of the switching surges, and it is time that you decide about the future of your motor. To look at the various instruments used to test a motor please visit: Ken Crawford, DuPont and Kent Haggerty, DuPont – “Test Before Touch” Easier Said Than Done.

Conclusion

Contemporary electrical protection patterns regularly do not take into consideration the significance of electric motor testing for appropriate equipment period and plant competitiveness. Motor testing has to be conducted to improve the equipment and make it available at any time, thereby decreasing capital expenditure. Appropriate prognostic and precautionary repairs should be conducted to reduce motor failures. Therefore it is imperative for electricians and trained workers to equip themselves with precise tools. How to test a three-phase electric motor has been discussed in this article.

Comments are closed