Alternating current generators or alternators as they are more popularly known are work on the principle of electromagnetic induction and consist of a stationery armature and a rotating field rotor. In the next couple of articles we will take a brief look at alternator construction studying its different parts one by one and learning about their construction starting with alternator stators

First of all let us start by learning what are the advantages of a stationary armature system, rather than the other way round (as is normally the case in DC generators where armature rotates)

· Since the output current of the generator is generated in the armature, it is much easier to extract this current for external use from the stationary armature rather than from a rotating armature wherein the brushes come into the picture and the associated challenges of using brush contacts for transferring current.

· Secondly it is much easier to insulate the stationary armature winding for high voltages which are normally in the region of over 30 KV.

· Thirdly apart from insulation it is also easier to brace these windings to prevent any deformation.

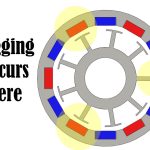

The figures below show images related to stator assembly and the arrangement of coils etc.

Stator Construction

Stator Frame and Rotor Construction

The stator frame is used to hold the armature windings in alternators, and in case of larger diameter alternators (which are slow speed) the stator frame is cast out of sections and there are holes for ventilation in the casting itself. The recent trends towards such stator construction are more in favour of using mild steel plates which are welded together rather than using castings.

Another integral part of the stator is the stator core which is supposed by the stator frame. Actually you can see the combined diagram of both the stator core as well as the stator frame (first of the three diagrams above). The core is constructed in the form of laminations and the material used for the same is either magnetic iron or steel alloy. The main purpose of lamination is to prevent loss of energy in the form of eddy currents. There are different types of armature slots provided in the core to insert the conductors and the three various types are as follows

· Wide open type slots

· Semi closed type slots

· Close type slots

Whereas the wide open slots are easier from the winding and repair perspective, they are also having a disadvantage that improper distribution of air gap flux.

The fully closed one on the other hand are good from this air gap flux perspective but obviously the initial construction and labour involved in such winding is substantially more in this case.

The semi closed presents an optimum mix of both these but then the actual design used is decided by the design specialist based on combined effect of all factors involved.