Servomechanism, automatic device used to correct the performance of a mechanism by means of an error-sensing feedback. The term servomechanism properly applies only to systems in which the feedback and error-correction signals control mechanical position or one of its derivatives such as velocity or acceleration. Servomechanisms were first used in gunlaying (aiming) and in fire-control and marine-navigation equipment. Today, applications of servomechanisms include their use in automatic machine tools, satellite-tracking antennas, celestial-tracking systems on telescopes, automatic navigation systems, and antiaircraft-gun control systems.

In many applications, servomechanisms allow high-powered devices to be controlled by signals from devices of much lower power. The operation of the high-powered device results from a signal (called the error, or difference, signal) generated from a comparison of the desired position of the high-powered device with its actual position. The ratio between the power of the control signal and that of the device controlled can be on the order of billions to one.

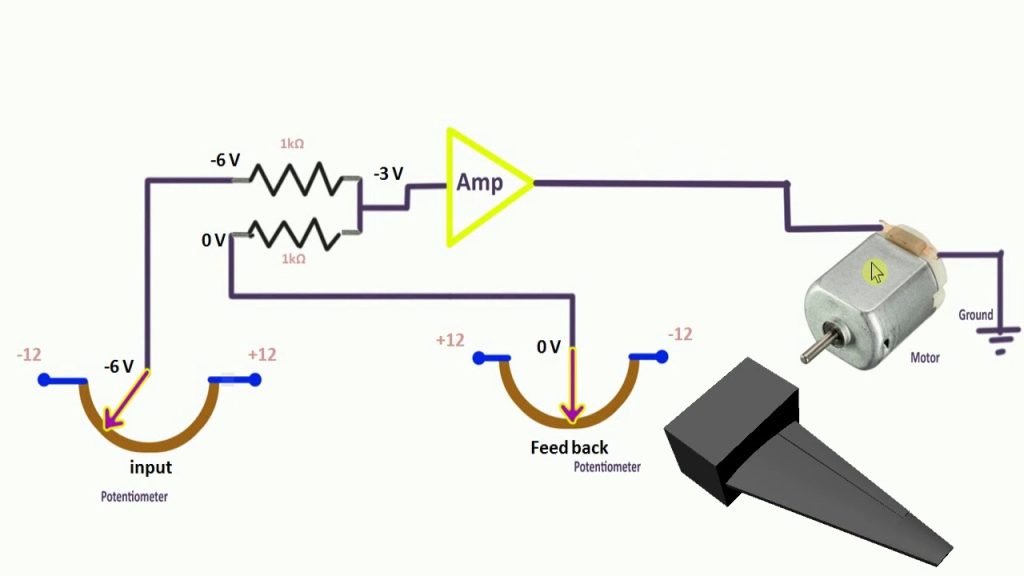

All servomechanisms have at least these basic components: a controlled device, a command device, an error detector, an error-signal amplifier, and a device to perform any necessary error corrections (the servomotor). In the controlled device, that which is being regulated is usually position. This device must, therefore, have some means of generating a signal (such as a voltage), called the feedback signal, that represents its current position. This signal is sent to an error-detecting device. The command device receives information, usually from outside the system, that represents the desired position of the controlled device. This information is converted to a form usable by the system (such as a voltage) and is fed to the same error detector as is the signal from the controlled device. The error detector compares the feedback signal (representing actual position) with the command signal (representing desired position). Any discrepancy results in an error signal that represents the correction necessary to bring the controlled device to its desired position. The error-correction signal is sent to an amplifier, and the amplified voltage is used to drive the servomotor, which repositions the controlled device.

A typical system using a servomechanism is the communications-satellite–tracking antenna of a satellite Earth station. The objective is to keep the antenna aimed directly at the communications satellite in order to receive and transmit the strongest possible signal. One method used to accomplish this is to compare the signals from the satellite as received by two or more closely positioned receiving elements on the antenna. Any difference in the strengths of the signals received by these elements results in a correction signal being sent to the antenna servomotor. This continuous feedback method allows a terrestrial antenna to be aimed at a satellite 37,007 km (23,000 miles) above the Earth to an accuracy measured in hundredths of a centimetre.

Comments are closed