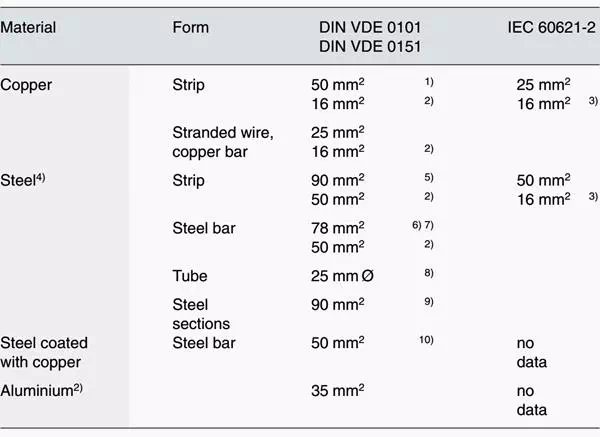

Earth electrodes (under ground) and earthing conductors (above ground) must conform to specific minimum dimensions regarding mechanical stability and possible corrosion resistance as listed in Table 1.

Table 1 – Minimum dimensions for earth electrodes and earthing conductors

Minimum dimensions for earth electrodes and earthing conductors

Minimum dimensions for earth electrodes and earthing conductors

Where:

1. Minimum thickness 2 mm

2. For above-ground earthing conductors only

3. For conductors protected against corrosion

4. When laid in the soil: hot-dip galvanized (minimum coating 70 µm)

5. Minimum thickness 3 mm (3.5 mm as per DIN 48801 and DIN VDE 0185)

6. Equivalent to 10 mm diameter

7. With composite deep ground electrodes: at least 16 mm diameter.

8. Minimum wall thickness 2 mm

9. Minimum thickness 3 mm

10. For steel wire, copper coating: 20 % of the steel cross section (min. 35 mm2), for composite deep ground electrodes: minimum 15 mm diameter

Selection of material for earth electrodes with respect to corrosion (no connection to other materials) may be made in accordance with the following points (DIN VDE 0151):

Hot-dip galvanized steel is very durable in almost all soil types. Hot-galvanized steel is also suitable for embedding in concrete.

· Contrary to DIN 1045, foundation earths, earthing conductors embedded in concrete, equipotential bonding conductors and lightning conductor leads of galvanized steel can be connected to reinforcing steel if the joints are not subjected to prolonged temperatures higher than 40 °C.

Copper is suitable as an earth electrode material in power systems with high fault currents because of its significantly greater electrical conductivity compared to steel. Bare copper is generally very durable in the soil.

Copper coated with tin or zinc is, like bare copper, generally very durable in the soil. Tinplated copper has no electrochemical advantage over bare copper.

Copper with lead sheath. Lead tends to form a good protective layer underground and is therefore durable in many soil types. However, it may be subject to corrosion in a strongly alkaline environment (pH values ≥ 10).

· IMPORTANT! For this reason, lead should not be directly embedded in concrete. The sheath may corrode under ground if it is damaged.

To conclude…

The earthing system is the basis for the entire electrical system. Together with the equipotential bonding system, a conductive and low-resistance connection to the local earth is created.

Voltage differences between the connected parts are shorted and a reference potential is generated. The safety conditions and switch-off systems can only reach their protection aims when the system is implemented correctly.

Besides correct planning, the installation must be checked and documented. The continued protective action of the earthing system must be ensured through regular maintenance and testing. Besides the state of the art and the named standards, the directives of the local power generating company must be complied with.

A correctly installed earthing system, together with lightning and surge protection devices, can minimize damage and failures.