Thermal power plants (including those that use fissile elements or burn coal, petroleum, or natural gas), and heat engines in general, do not convert all of their thermal energy into electricity. In most heat engines, a bit more than half is lost as excess heat (see: Second law of thermodynamics and Carnot’s theorem). By capturing the excess heat, CHP uses heat that would be wasted in a conventional power plant, potentially reaching an efficiency of up to 80%, for the best conventional plants. This means that less fuel needs to be consumed to produce the same amount of useful energy. Steam turbines for cogeneration are designed for extraction of steam at lower pressures after it has passed through a number of turbine stages, or they may be designed for final exhaust at back pressure (noncondensing), or both. A typical power generation turbine in a paper mill may have extraction pressures of 160 psig (1.103 MPa) and 60 psig (0.41 MPa). A typical back pressure may be 60 psig (0.41 MPa). In practice these pressures are custom designed for each facility. The extracted or exhaust steam is used for process heating, such as drying paper, evaporation, heat for chemical reactions or distillation. Steam at ordinary process heating conditions still has a considerable amount of enthalpy that could be used for power generation, so cogeneration has lost opportunity cost. Conversely, simply generating steam at process pressure instead of high enough pressure to generate power at the top end also has lost opportunity cost. The capital and operating cost of high pressure boilers, turbines and generators are substantial, and this equipment is normally operated continuously, which usually limits self-generated power to large-scale operations.

· Large cogeneration systems provide heating water and power for an industrial site or an entire town. Common CHP plant types are:

· Gas turbine CHP plants using the waste heat in the flue gas of gas turbines. The fuel used is typically natural gas

· Gas engine CHP plants use a reciprocating gas engine which is generally more competitive than a gas turbine up to about 5 MW. The gaseous fuel used is normally natural gas. These plants are generally manufactured as fully packaged units that can be installed within a plant room or external plant compound with simple connections to the site’s gas supply and electrical distribution and heating systems. Biofuel engine CHP plants use an adapted reciprocating gas engine or diesel engine, depending upon which biofuel is being used, and are otherwise very similar in design to a Gas engine CHP plant. The advantage of using a biofuel is one of reduced hydrocarbon fuel consumption and thus reduced carbon emissions. These plants are generally manufactured as fully packaged units that can be installed within a plant room or external plant compound with simple connections to the site’s electrical distribution and heating systems. Another variant is the wood gasifier CHP plant whereby a wood pellet or wood chip biofuel is gasified in a zero oxygen high temperature environment; the resulting gas is then used to power the gas engine.

· Combined cycle power plants adapted for CHP

· Molten-carbonate fuel cells and solid oxide fuel cells have a hot exhaust, very suitable for heating.

· Steam turbine CHP plants that use the heating system as the steam condenser for the steam turbine.

· Nuclear power plants, similar to other steam turbine power plants, can be fitted with extractions in the turbines to bleed partially expanded steam to a heating system. With a heating system temperature of 95 °C it is possible to extract about 10 MW heat for every MW electricity lost. With a temperature of 130 °C the gain is slightly smaller, about 7 MW for every MWe lost.

Heat recovery steam generators

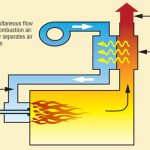

A heat recovery steam generator (HRSG) is a steam boiler that uses hot exhaust gases from the gas turbines or reciprocating engines in a CHP plant to heat up water and generate steam. The steam, in turn, drives a steam turbine or is used in industrial processes that require heat.

HRSGs used in the CHP industry are distinguished from conventional steam generators by the following main features:

The HRSG is designed based upon the specific features of the gas turbine or reciprocating engine that it will be coupled to.

Since the exhaust gas temperature is relatively low, heat transmission is accomplished mainly through convection.

The exhaust gas velocity is limited by the need to keep head losses down. Thus, the transmission coefficient is low, which calls for a large heating surface area.

Since the temperature difference between the hot gases and the fluid to be heated (steam or water) is low, and with the heat transmission coefficient being low as well, the evaporator and economizer are designed with plate fin heat exchangers.